風との対話から生まれる、

イノベイティブな商品開発と

メイドインジャパンの高品質なものづくり

ラジエーターの役割はエンジンを冷やすこと。

クルマはラジエーターが機能しないと

走ることはできない。

コアな部分だからこそ、

本物とそうでないものの差は歴然だ。

私たちの想いはひとつ。

「本物の走りを叶える

最高のラジエーターをつくること」

DRLの原点は、

気候や温度など厳しい走行条件や

環境を気にすることなく、

伸びやかな走りに挑戦するドライバーの

気持ちに寄り添うものづくり。

デザイン思考で導かれる自由な発想をもとに、

ゼロからの開発に挑戦し、

設計、検証、改良を得て

製品化に至るまで、

妥協のないプロセスを重ねることで、

ドライバーの走りと挑戦を力強く支える

「本当に良いもの」を生み出してゆきたい。

”走ることに夢中になる人”に、”走る楽しみ”を

もっと感じてもらえるように。

私たちは日本のメーカーとして、

そして走りの一ファンとして

考え得る最高のラジエーターを

今日もつくり続けます。

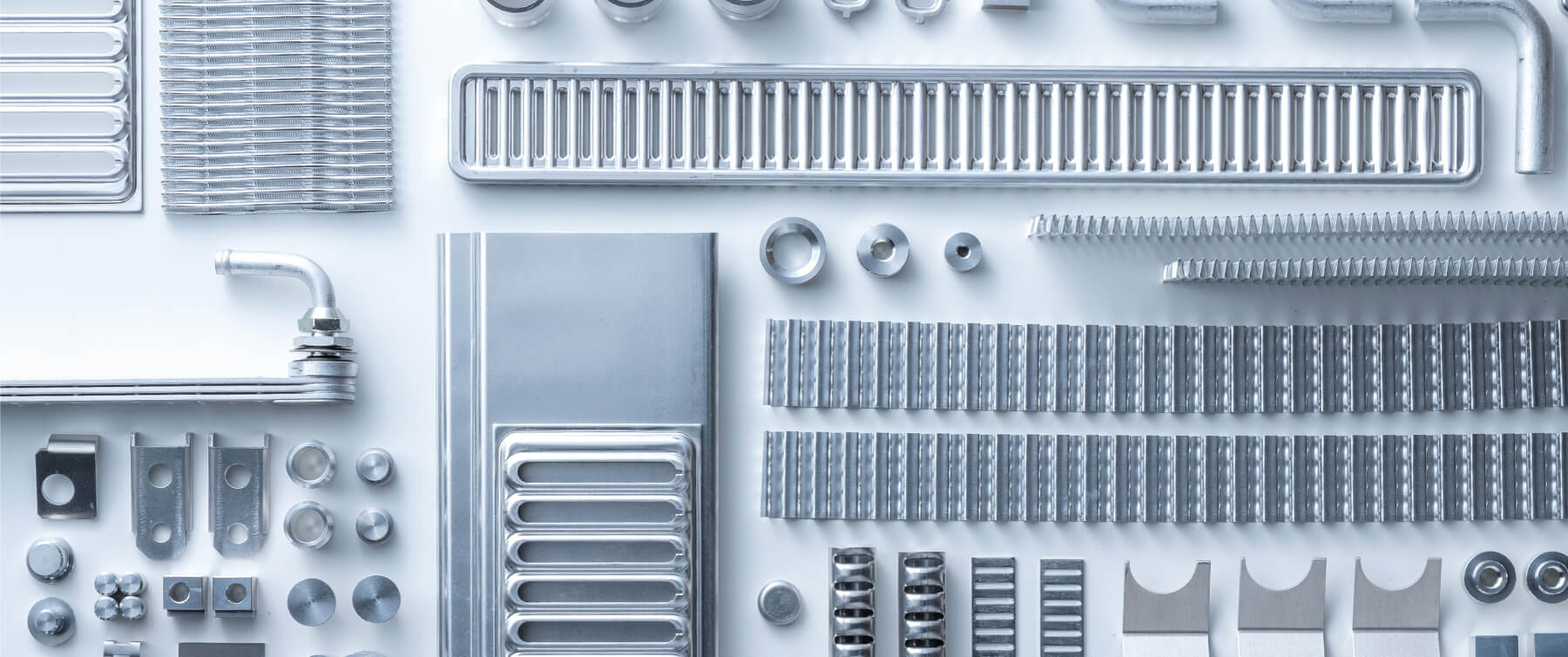

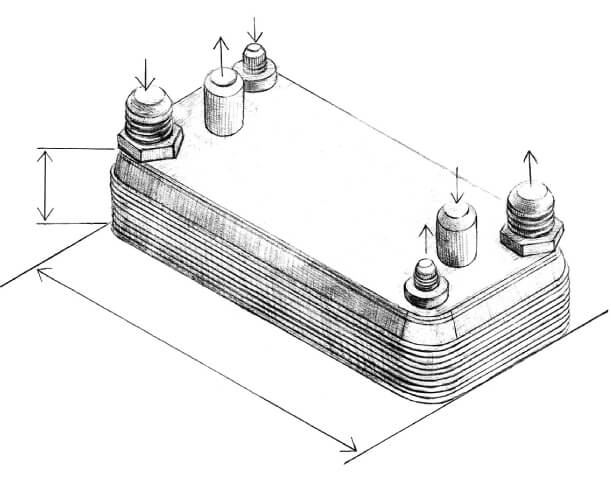

ひとつの部品 加工のプロセス・形状 そこに宿るイノベーションは 風と熱の関係をシンプルに 見つめ直すことから生まれました

ひとつの部品 加工のプロセス・形状 そこに宿るイノベーションは 風と熱の関係をシンプルに 見つめ直すことから 生まれました

The production process, the shape,

and the innovation embedded within each part

are all borne out from the insights gleaned simply

by looking into the essence of the relationship between airflow and heat.

Innovation

DRLの開発

デザイン思考が導く自由な発想

- 革新を生む、

固定概念にとらわれない商品開発 -

前例にとらわれず本質を考え抜くことで、業界をリードするDRLの技術開発。その一例が、逆転発想による薄型コンパクトなラジエーター形状です。

実車テストを何度も重ねて風の流れを追求した結果、コアは厚いほうが冷却効率が高いという定石を覆し、コア圧を薄くすることで空気を滞留させない「36mm」の薄型コアが生まれました。 - 反復型の開発体制が

0→1をつくりだす -

ゼロからの挑戦が、

これまでにない新しいものを生み出す。

設計デザイン、試作、実装テストのプロセスを、

短いサイクルで繰り返す反復型の開発体制で、

スピーディーな製品開発を実現します。

開発の進行状況をチームで共有し、

改善を重ねることで、

市場の期待に応え、

顧客の要望に寄り添う製品を生み出しています。 - グループの総合力で

間に合わせではない本物を生み出す -

60年超の歴史を持つ熱交換器専門メーカーとして、集積された技術力とノウハウをベースにした質の高いものづくり。

世界トップレベルの水準を要求されるレーシングカーにも採用される高品質の製品開発力は、グループ内に還流され、車載用熱交換器や、内外の各自動車メーカーのアフター製品等のさまざまな商品に展開されています。

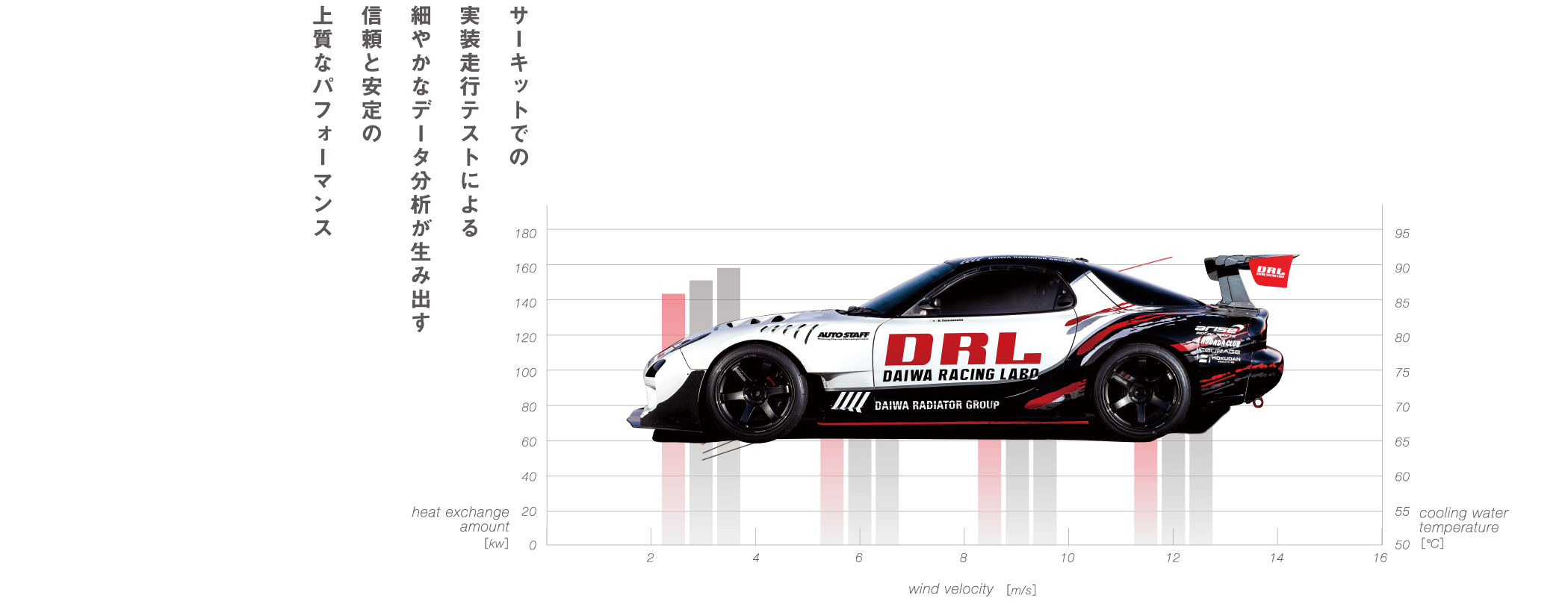

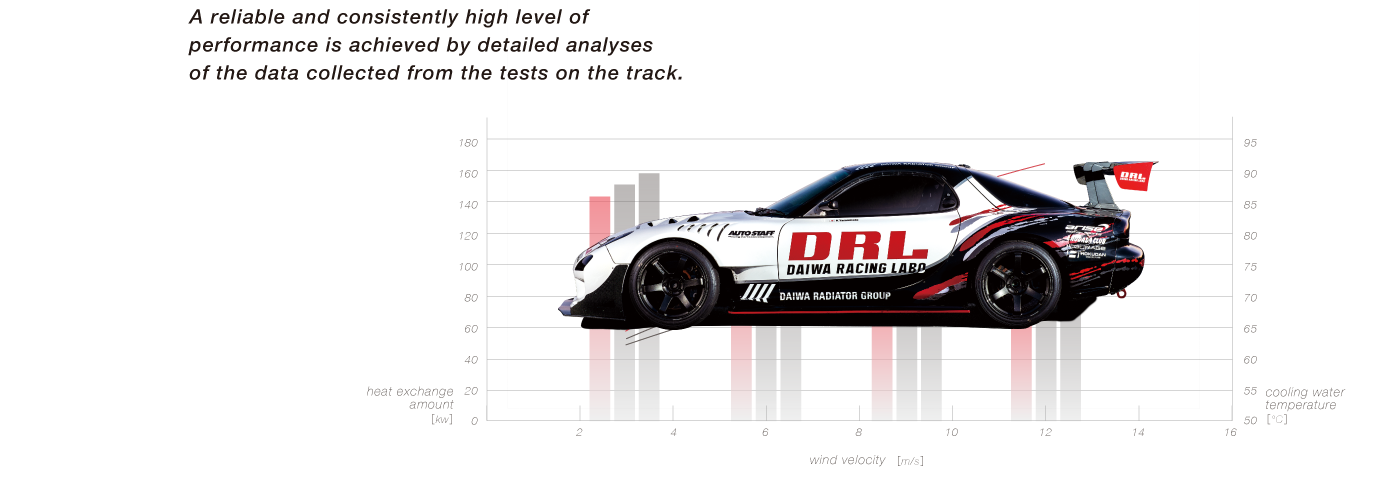

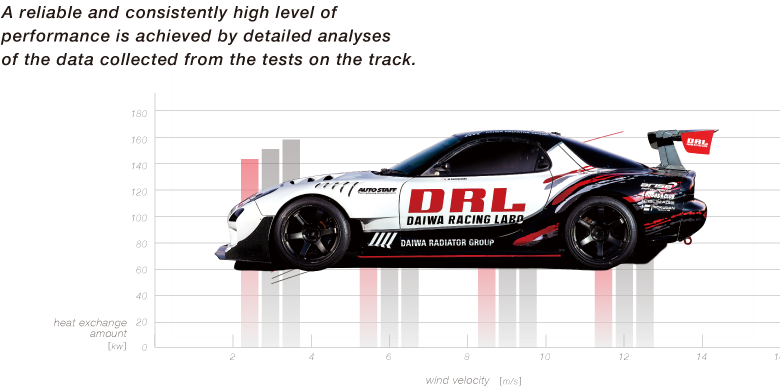

Performance

ハイパフォーマンス 熱交換システム

実装テストと分析を繰り返し

ハイパフォーマンスを実現する

- 走りの結果を引き出す

実装テストによる地道な分析 -

“どんなに優れた製品も、

現場でのパフォーマンスが出せなければ意味がない”

DRLでは、革新的な発想をベースにした設計デザインを、

独自開発の放熱計算ソフトでシュミレーションを重ね、

走行環境や気温など、様々な条件下で展開される

激しいレースシーンを想定した

実装テストを繰り返すことで具現化させてきました。

エンジンの実力を最大限に引き出すこと、

それこそが本当に優れた熱交換製品として評価される大切な要素。

確かな技術とチーム力で、チューニングの現場の声と

進化し続ける自動車の技術革新に応え、改良を重ねています。

Manufacturing

製品

ドライバーの走りと挑戦を

力強くしなやかに支える製品を

- クルマの進化とともに。

最先端の技術と安心の国内一貫生産 -

DRLは、熱交換器の専門メーカー・大和ラジヱーター工業株式会社の研究開発を担う、株式会社大和ラヂエーター製作所のプロダクトブランド。

クルマの進化にあわせた最先端の技術に対応し、レーシングに象徴される 最も厳しいコンディションを想定した独自の製品開発を行なっています。 製品は安心の国内一貫生産、DRLの専属エンジニアによる手仕上げです。 サイズや仕様など、カーオーナー様のご要望にあわせたカスタマイズ(ワンオフ)にも対応いたします。

DRL to the future

未来へつながる

長い関係をめざして

伸びやかに、自由に乗りこなすこと。

それはドライビングの楽しさであり、

これからも変わらないこと。

走る楽しみと、そこから生まれる

コミュニケーションを大切に

ドライバーの期待に応える

製品づくりを通じて、

未来へつながる深く長いパートナーシップを

目指しています。

DRL to the future

- 所在地

- 〒733-0006

広島県広島市西区三篠北町1-34

- TEL

- 082-509-0663

- FAX

- 082-509-0668

- 設立

- 1955年11月01日

- 資本金

- 4,550万円

- 所在地

- 〒733-0006

広島県広島市西区三篠北町1-34

- TEL

- 082-509-0663

- FAX

- 082-509-0668

- 設立

- 1955年11月01日

- 資本金

- 4,550万円